Oilmec’s Bow Spring Centralizers are designed and manufactured to assist casing running and cementing. Starting, running, and restoring force tests are performed to confirm that centralization products consistently exceed the requirements of API Specification 10D for centralizers. The tests are conducted at Oilmec’s state-of-the-art testing facility, which features a fully computerized centralizer test bench.

Hinged Welded Cement Basket is designed with Flexible Bow Springs, heat-treated under

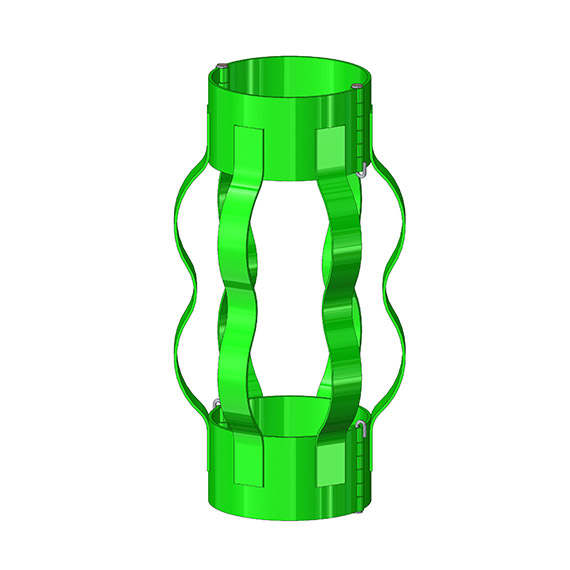

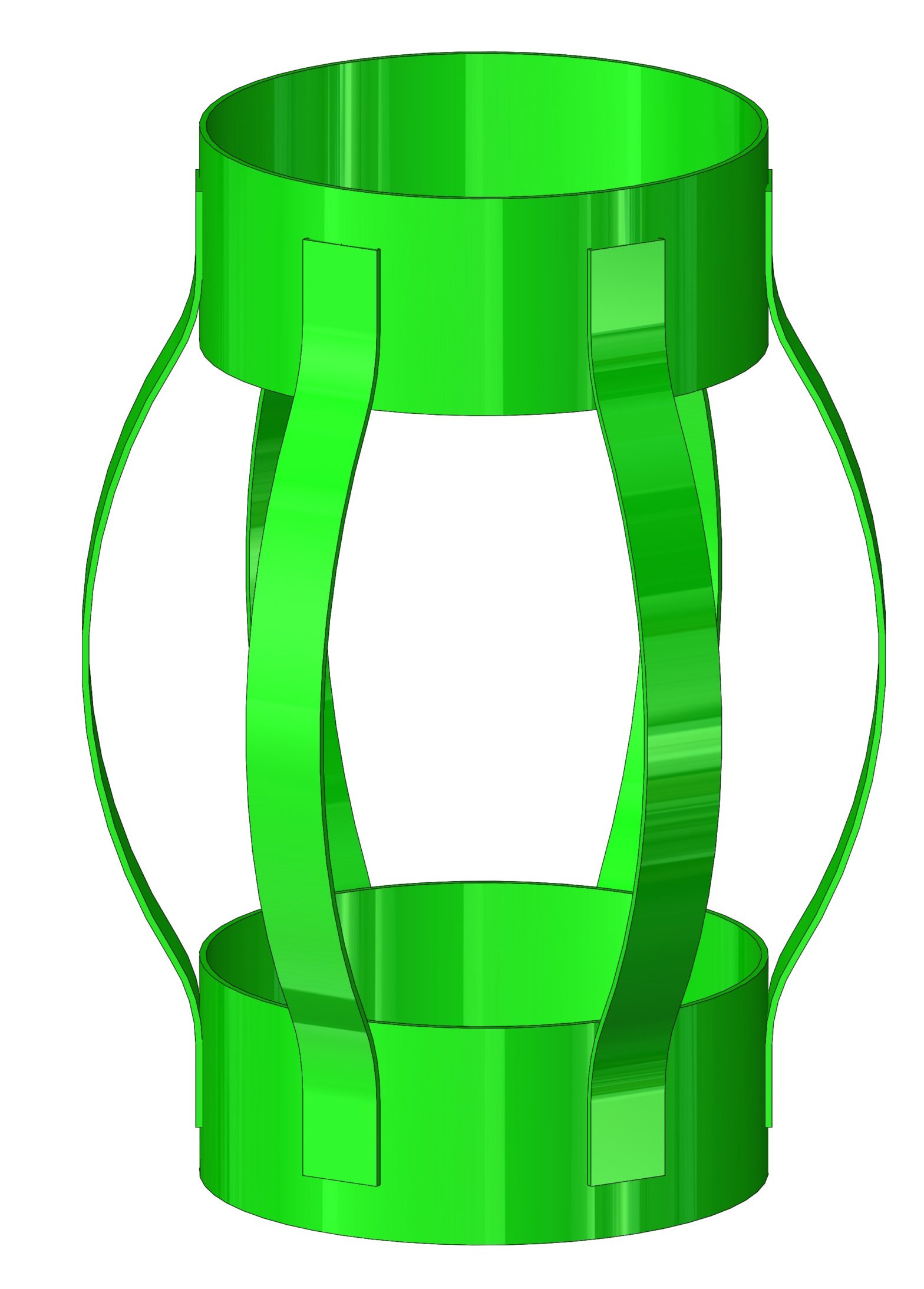

Slip On Welded Semi-Rigid Centralizers share many of the same design and operational

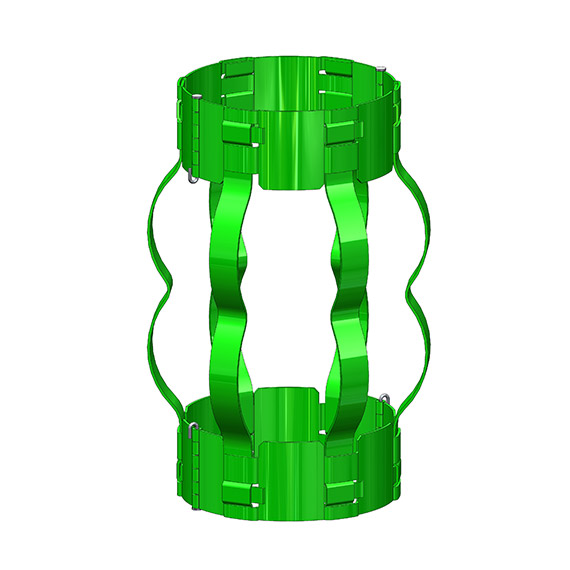

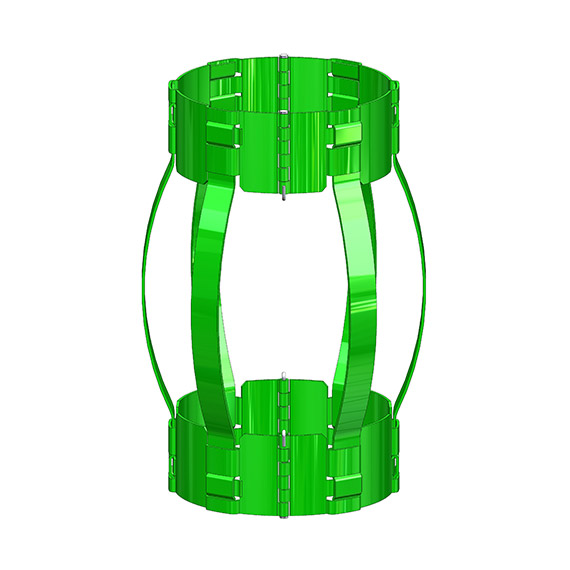

Hinged Welded Semi Rigid Centralizer ensures high efficiency in casing. Welded Centralizer

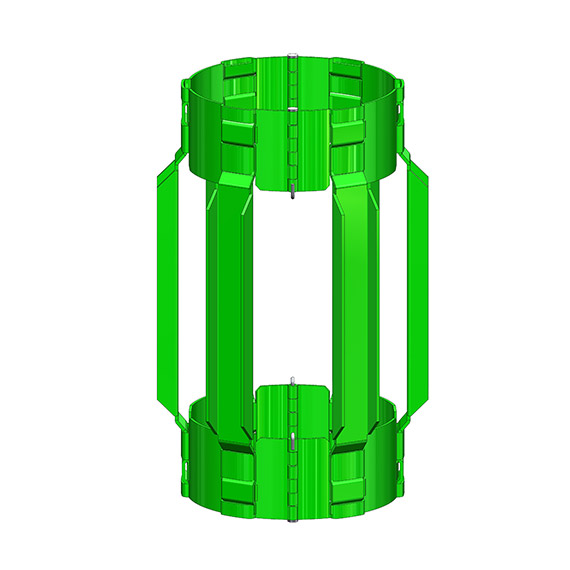

Hinged Non Weld Semi-rigid bow centralizer withstands high lateral loads and is specially

Designed for positive centralization of casing pipe for highly deviated and horizontal wells fitted

Drill Pipe Centralizer Runs freely into difficult well-bores while providing excellent standoff. The

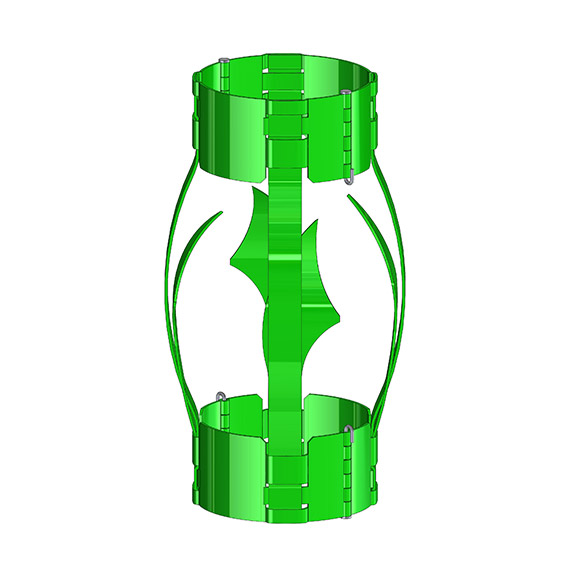

Slip on Welded Turbolizer has deflector blade fitted on standard bow spring

Welded Turbolizer has deflector blade fitted on standard bow spring which

Non Welded Turbolizer has deflector blade fitted on standard bow spring

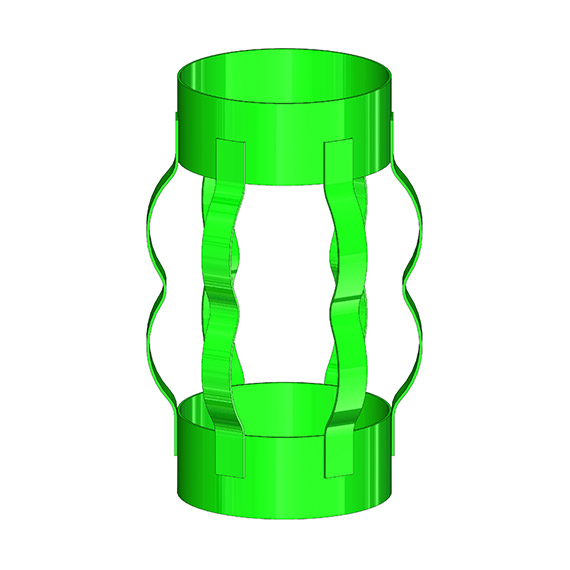

Single Piece Slip on Welded Bow Spring Centralizer is called Our

Slip on Welded Bow Spring Centralizer OM003 Notched Collar design allows for a

Bow springs manufactured from high quality spring steel and heat treated to achieve

Oilmec – Stainless Steel centralizers are special purpose centralizers it’s used where

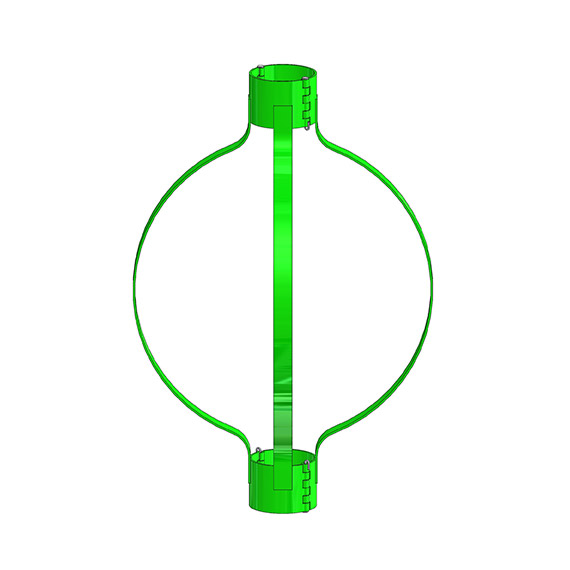

The Standard ‘Bow Spring’ range are hinged non-welded bow-spring centralizers designed to

Cement baskets protect weak formations from hydrostatic pressures exerted

Copyright © 2026 Oilmec Drilling Equipments Pvt. Ltd.

Developed by Abacus Desk