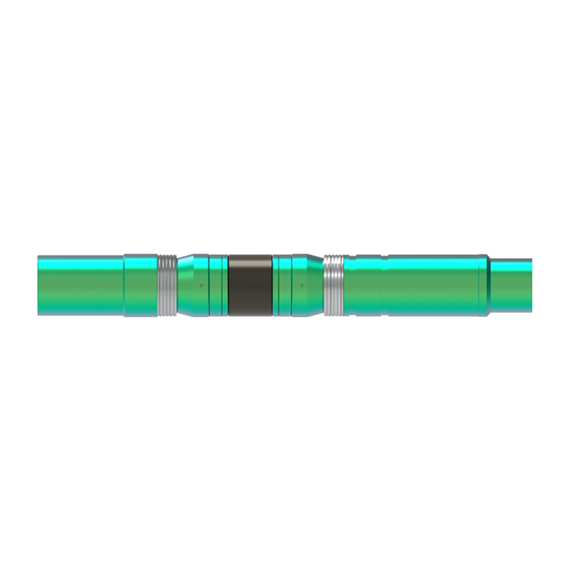

MODEL: OM-HSBP-1 [Single Bore] & OM-HSBP-2 [Double Bore]

These are hydraulic set permanent drillable packers. They have an enlarged seal bore to accept seal assemblies. In double bore the packer has an upper larger seal bore for anchor tools or seal accessories to be latched and sealed. The range and combination of bore sizes are designed such that all the accessories are commonly used for both the series of packers. The hydraulic setting mechanism makes the packers suitable for use in highly deviated or horizontal wells. Manufactured from special alloy grade material components, enables the packers to be used in a wide range of operating conditions.

Features/Benefits:

- Solid, slim lined construction and a packing element system which resists swab-off. This permits a fast run-in (when compared with earlier models of permanent packers) without fear of impact damage or premature setting, yet packs off securely and permanently when the packer is set

- Two opposed sets of full circle; full strength slips ensure that the packer will stay where it is set.

- Interlocked expandable metal back-up rings contact the casing and create a positive barrier to packing element extrusion.

- Setting requires no rotation or reciprocation, thereby eliminating the problems of spacing out, landing etc.

- Packers run with Anchor Seal Nipples.

- O-Rings are supported by back-up rings to better life seal integrity.

- Packers are rated up to 10,000 psi pressure differentials.

- Guides are furnished as per standard, to attach mill-out extensions; seal bore extensions or other equipment below the packer.

- All alloy materials within the packer are suitable for H2S service.

- Body & Guide (components in flow paths) can be furnished in customer’s choice of material.

- Fluid displacement is possible after well is flanged up and prior to setting the packer.

- Setting sequence of packer may be controlled to start at 1,500 psi