Oilmec’ Float Equipment is a key component for running casing and performing cementing operations. During Cementing operations, float equipment are essential for preventing back-flow while also serving as a landing point for wiping and displacement plugs when surge pressures on the formation are a concern, Oilmec’s Float Equipments can be configured to Auto fill to prevent formation damage. Our Float Equipment is manufactured to the highest quality specifications and meets or exceeds the highest API standards. Float Equipments are available in sizes 2 3/8’ to 36”. The above sizes are available on customer demand.

We offer a complete package of oilfield casing accessories tailored to each good design and application.

From centralizers and float equipment to stage tools and guide shoes, we provide specialized solutions for various specifications.

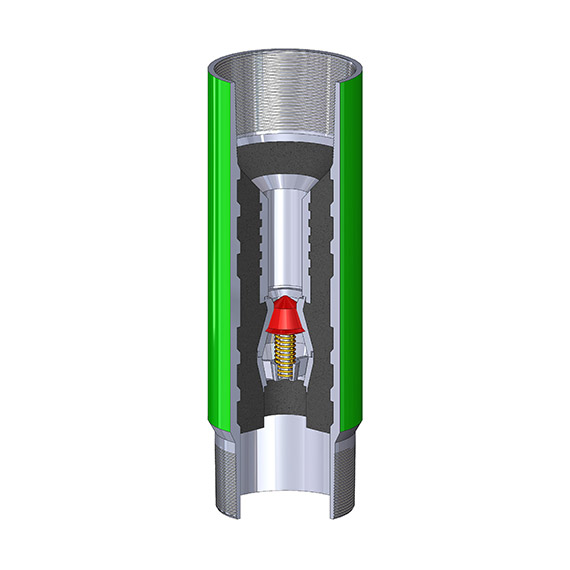

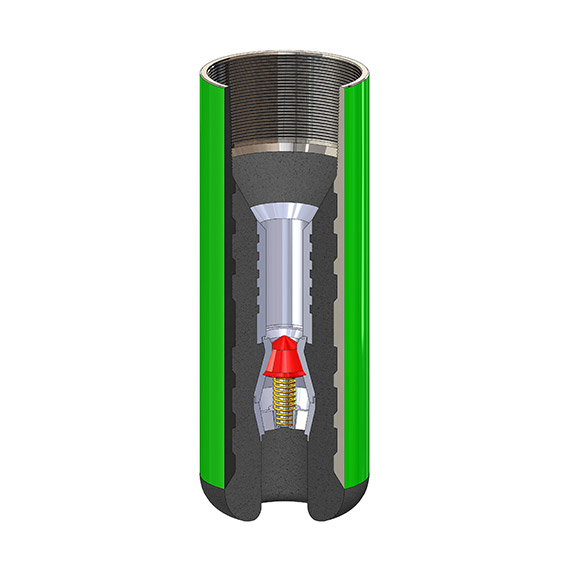

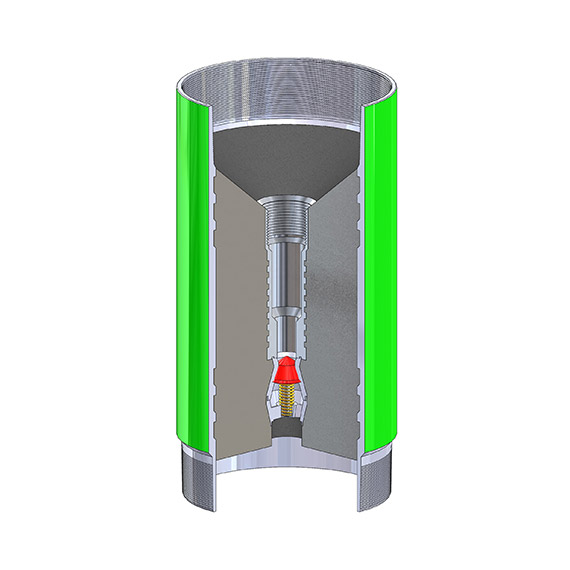

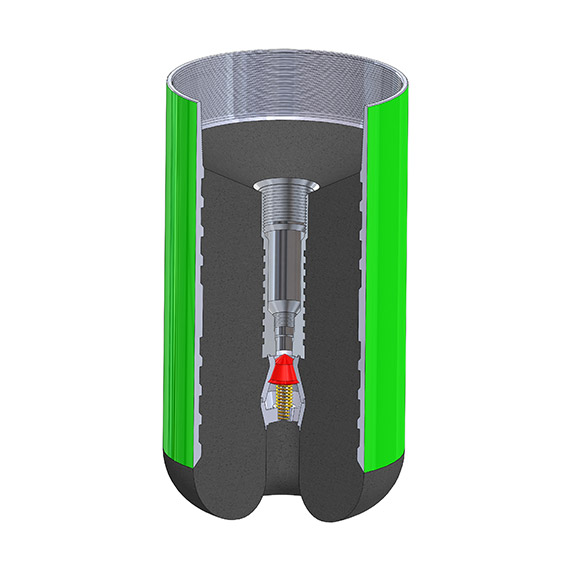

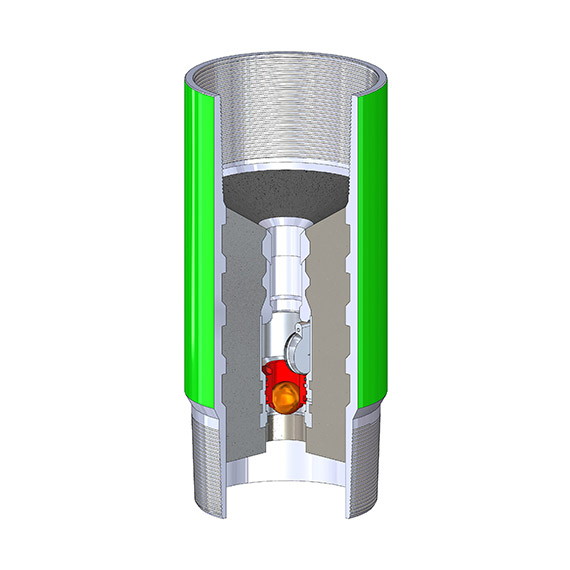

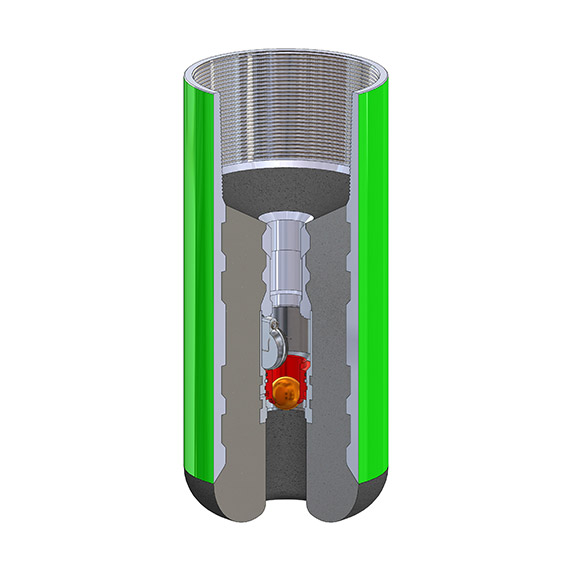

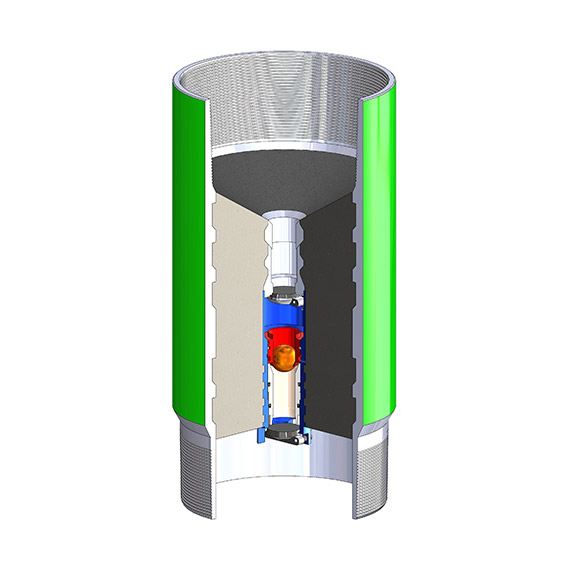

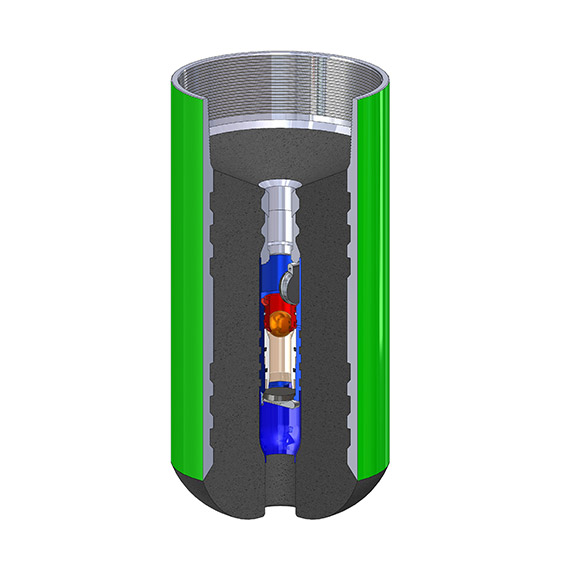

This design ensures the valve’s maximum circulation rate in vertical, horizontal, and deviational wells. The material used for float equipment is seamless casing-grade steel. Float equipment can be supplied in all grades of steel.

Oilmec’s Float equipment is tested and rated in compliance with API RP 1OF specs. The material used in the valves is High plastic. This valve is encased and held in place with the high-pressure cement mixture. The design and manufacturing process of the valve allows for maximum circulation rates. In addition, the Plunger Valve assembly fixed within the float Float equipment prevents the flow back of the cement slurry when pumping is stopped.

Centralizers and Float Equipment

We have the broadest range of cementing tools, including API casing pipes, bow springs, rigid centralizers, floating equipment, and other accessories for the Oil and Gas Drilling Industry. As a field expert, we will give you rich experience, professional field knowledge, and qualified products for our customers worldwide.

Float equipment is commonly used on the lower section of the excellent casing to:

· Reduce the strain on the derrick during placement of the casing in the wellbore

· Help guide the casing past ledges and sidewall cavings as the casing passes through deviated sections of the hole

· Provide a backpressure valve to prevent re-entry of cement into the casing inside diameter (ID) after it is pumped into the casing/wellbore annulus

· Provide a landing point for cementing plugs pumped in front of and behind the cement slurry

Cementing Equipment

Oil Well Cementing Equipment is essential for Oil/Gas exploration or production wells and is used as oilfield equipment while drilling a well.

Casing pipe will be installed at various depths while drilling. It is held in place by cement, which also provides zone isolation. The casing protects the wellbore from fluids, pressures, and stability problems. Down-hole equipment such as Centralizers and Turbolizers are used to ensure sound zone isolation. In addition, float Shoes and Collars (float valves) prevent backflow after the cement has been pumped into place.

Nose Orifice is sufficiently large as to allow conversion balls, tubes, and debris

Oilmec’s Reamer Shoe is designed specifically to be installed on Casing or Liner and Screen

A float collar is installed near the bottom of the casing string. Cement plugs land on it during the

A rounded profile float shoe with an integral check valve attached to the bottom of a casing string

A rounded profile float shoe with an integral check valve attached to the

Oilmec’s Stab-in Float Collars are provided with stab in profile for stab in cementing where the drill

With Stab-In cementing, the drill pipe is stabbed directly into the float shoe or collar and

Oilmec’ Stab in Latch in Float Collar receptacle has ratcheting left hand

Oilmec’ Stab in Latch in Float Shoe receptacle has ratcheting left hand

Oilmec’ Stab in Latch in Float Shoe receptacle has ratcheting left hand threads to lock the stinger

The Auto Fill Cement Float Shoe permits the casing to fill automatically while

Oilmec’s Differential fill up float Collar is provided with differential valve

Oilmec’s Differential fill up Shoe is provided with differential valve

Copyright © 2026 Oilmec Drilling Equipments Pvt. Ltd.

Developed by Abacus Desk