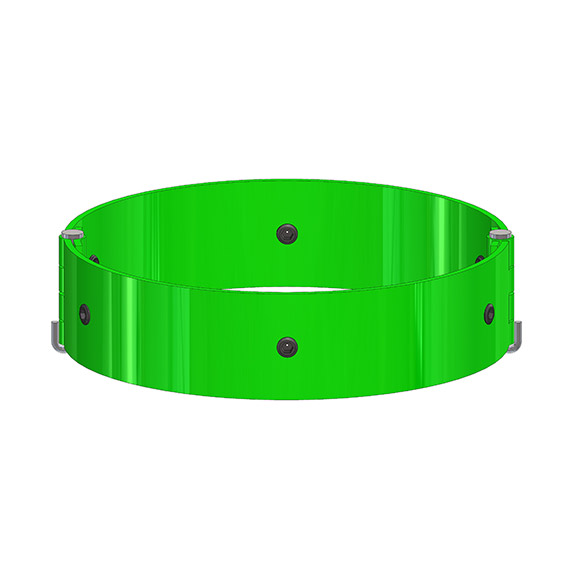

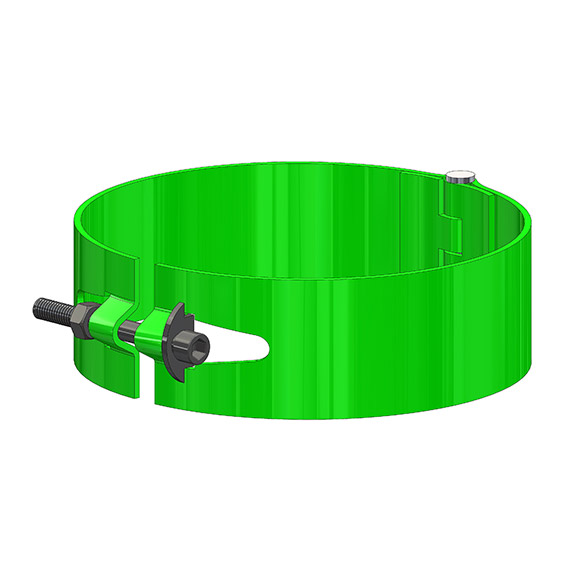

Oilmec has five primary styles of Stop Collars. The main motive of these stop collars is to keep centralizers and other casing attachment in proper place on the casing.

Oilmec offers both hinged and slip-on style of stop collars and are available in all sizes.

Features of hinged stop collars include

Features of slip-on stop collars include

As per requirement, for tight clearances, slip-on stop collar are available where as for semi-tight clearances, hinged stop collar are available.

Installed with set screws,Designed for use where higher

Designed to be latched on to the casing with set screws providing additional

Hinged Bolted Stop Collar is designed to latch-on to the casing without having

Utilizes two spiral locking pins which, when driven in firmly,

Copyright © 2026 Oilmec Drilling Equipments Pvt. Ltd.

Developed by Abacus Desk